Find out how Periskop helps Hazwat to revolutionize their composting process with accurate, real-time temperature monitoring.

Le Banga au chocolat

The Situation

Valerie, production manager at Le Banga au Chocolat in Mayotte, tells us more...

We set up Le Banga au Chocolat in Mayotte to revitalize local chocolate production with a group of local producers. Each year, we plant the equivalent of one hectare of cocoa trees on a number of farms.

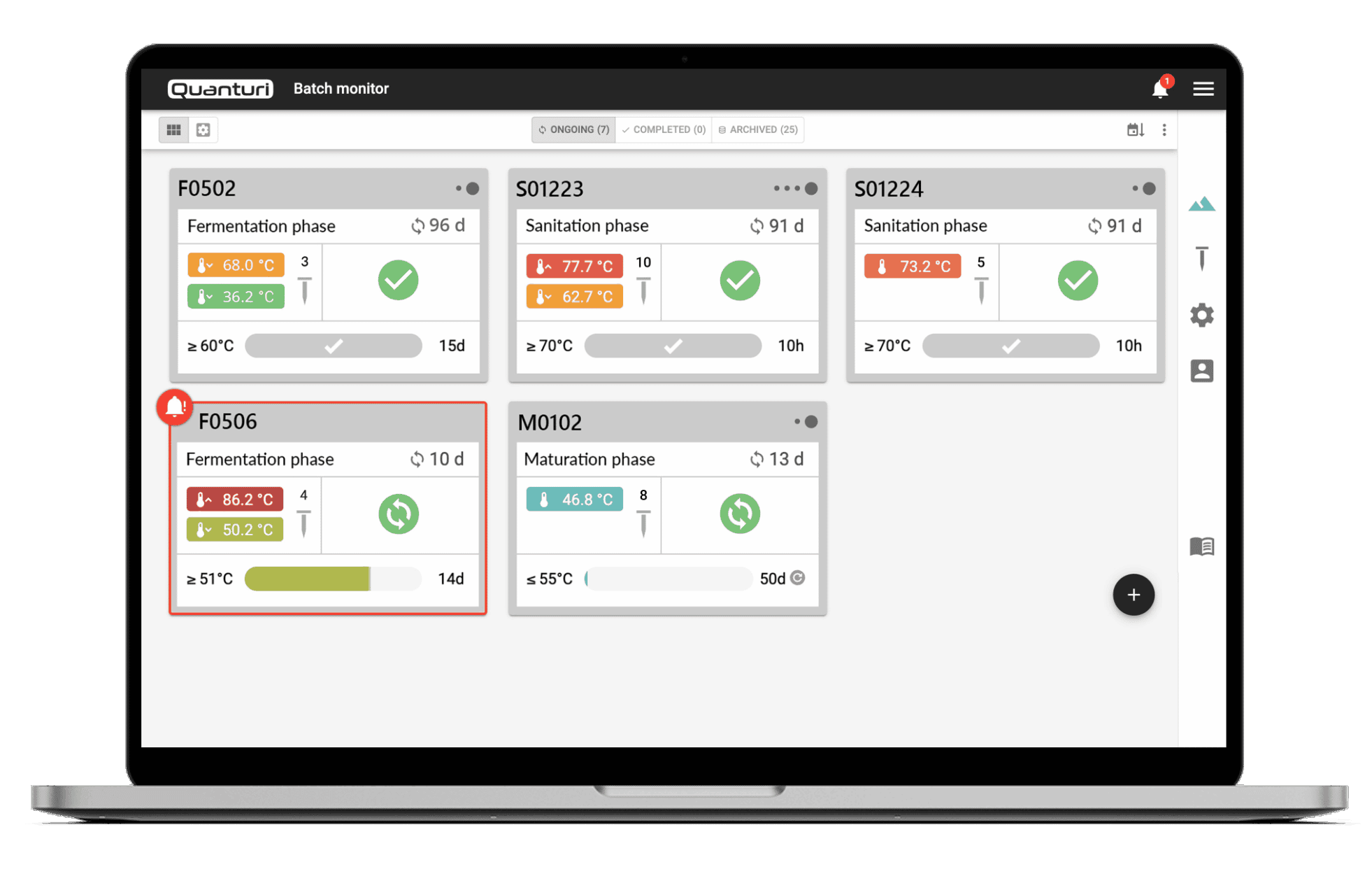

To transform our beans into the finished product, there are a number of necessary steps including fermentation, drying, roasting, and grinding. This is where Quanturi’s Periskop probes come into play and make our work much easier. We use them mainly for our chocolate production. We monitor the temperature of our raw material – our beans – and the temperature of our finished product, which is our chocolate.

The problem

Before we used Periskop, our bean fermentation was less accurate

Of all the processes involved in making chocolate, fermentation is the most difficult. It is a complex biological process that is difficult to master on our scale of a few dozen kilos of beans.

During the fermentation process, which lasts six days, the beans rise in temperature for about 40 hours before cooling back down. During this phase, the beans must be stirred to switch from anaerobic alcoholic fermentation to aerobic acetic fermentation. It is this increase in temperature and the acetic acid generated which cause the beans to modify greatly.

Without monitoring temperature, it was difficult for us to know precisely when the beans needed stirring to spark the fermentation process as and when necessary.

OUR SOLUTION

Periskop gives us perfect cocoa bean fermentation

We use the probes in our chocolate preparation workshop as part of our tree-to-bar process. By monitoring bean temperature during fermentation, we can see exactly when fermentation is dropping off and when the temperature starts to fall. So we know exactly when to stir the beans again to re-oxygenate and revitalize the fermentation process. We also monitor our stock of finished product to make sure the texture doesn’t change with the weather.

- A fermentation process that is difficult to control

- A stock of finished product that is subject to weather conditions

- A small scale of production with strict requirements

THE IMPACT OF OUR SET-UP

Periskop probes enable us to guarantee our chocolate production

We use Periskop probes to ensure correct fermentation of our cocoa beans and to monitor our chocolate stock. Our chocolate is produced in Mayotte where the tropical climate means that temperatures are often high, bringing the risk of melting. By monitoring the temperature of our chocolate, we can ensure that it stays dry and we can react quickly if heat becomes a problem.

High quality production

Periskop probes enable us to monitor the temperature of our beans in real time. This ensures that we track the fermentation process correctly, preventing under-fermentation or worse still, over-fermentation, which causes the chocolate to have an unpleasant flavor. So, we can be sure that our chocolate has the best possible taste.

-

Mechanically and chemically robust probes

During the alcoholic fermentation phase, cocoa beans produce acetic acid. Periskop probes are robust and resistant to all environments, even the most corrosive. So, the mechanically and chemically robust probes can be placed in the beans during fermentation, enabling us to monitor the first rise in temperature caused by the alcoholic fermentation of the sugar present in the cocoa pulp. This means that we can guarantee perfect fermentation.

Would you like to benefit from Quanturi’s solutions too?

Our team of compost and fermentable material specialists is on hand to answer all your questions.

Our solution used by our customers

Find out how Periskop improved their waste monitoring processes.

ValorBioCompost

Find out how Periskop helps ValorBioCompost to collect and analyze data, secure its site and improve its processes.

Neocomp

Find out how the Periskop application and probes help Neocomp improve its data measurement, storage and analysis.