Compost ventilation control system

Optimize Composting Efficiency with Advanced Ventilation Control

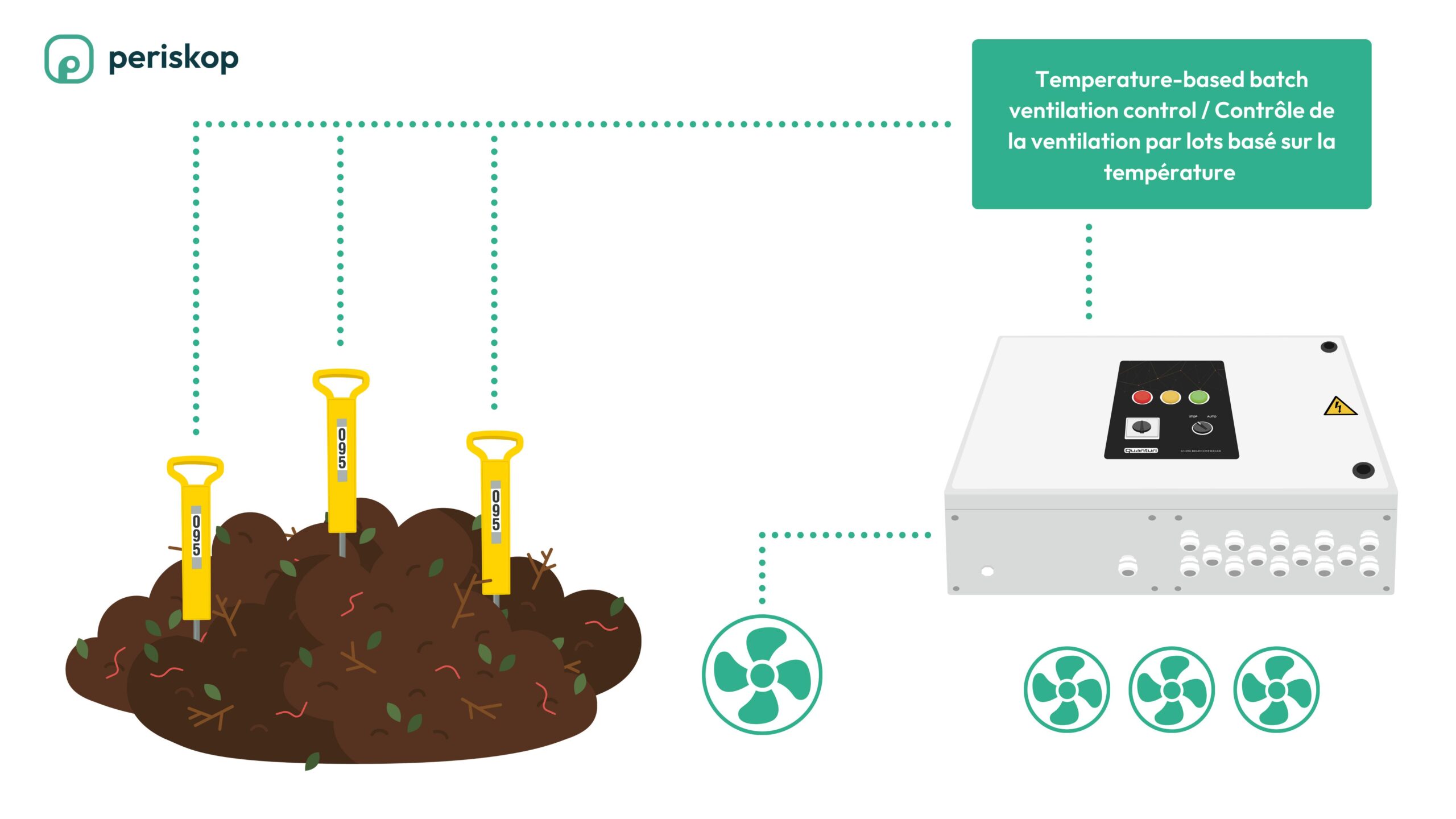

What is the RC12 compost ventilation control system?

The RC12 is a smart controller that optimizes ventilation in composting facilities. It remotely manages each ventilation line for quicker temperature control and lower energy costs throughout the composting process. The RC12 enhances and simplifies ventilation management in composting facilities by combining multiple strategies. It ensures faster achievement of optimal compost quality through precise temperature control and streamlined automation. Facilities are secured by preventing dangerous temperatures. The user-friendly interface and data synchronization simplify monitoring, control, and cost optimization for both existing and new facilities.

Compost ventilation controller features

Reduce energy costs

Automate your ventilation strategy based on your

electricity contract’s peak and off-peak pricing periods.

Remote access

Control and monitor your system from anywhere using a user-friendy application.

Individual fan control

Precisely manage each fan to ensure optimal

oxygenation and rapid temperature target achievement.

Fire safety

Automatically cool the windrow through continuous ventilation until

a safe temperature is reached in case of a runaway composting process.

Temperature controlled ventilation

Set temperature targets, define ventilation cycles tailored to the compost composition, and take into account

adverse weather conditions.

How does the RC12 manage compost ventilation?

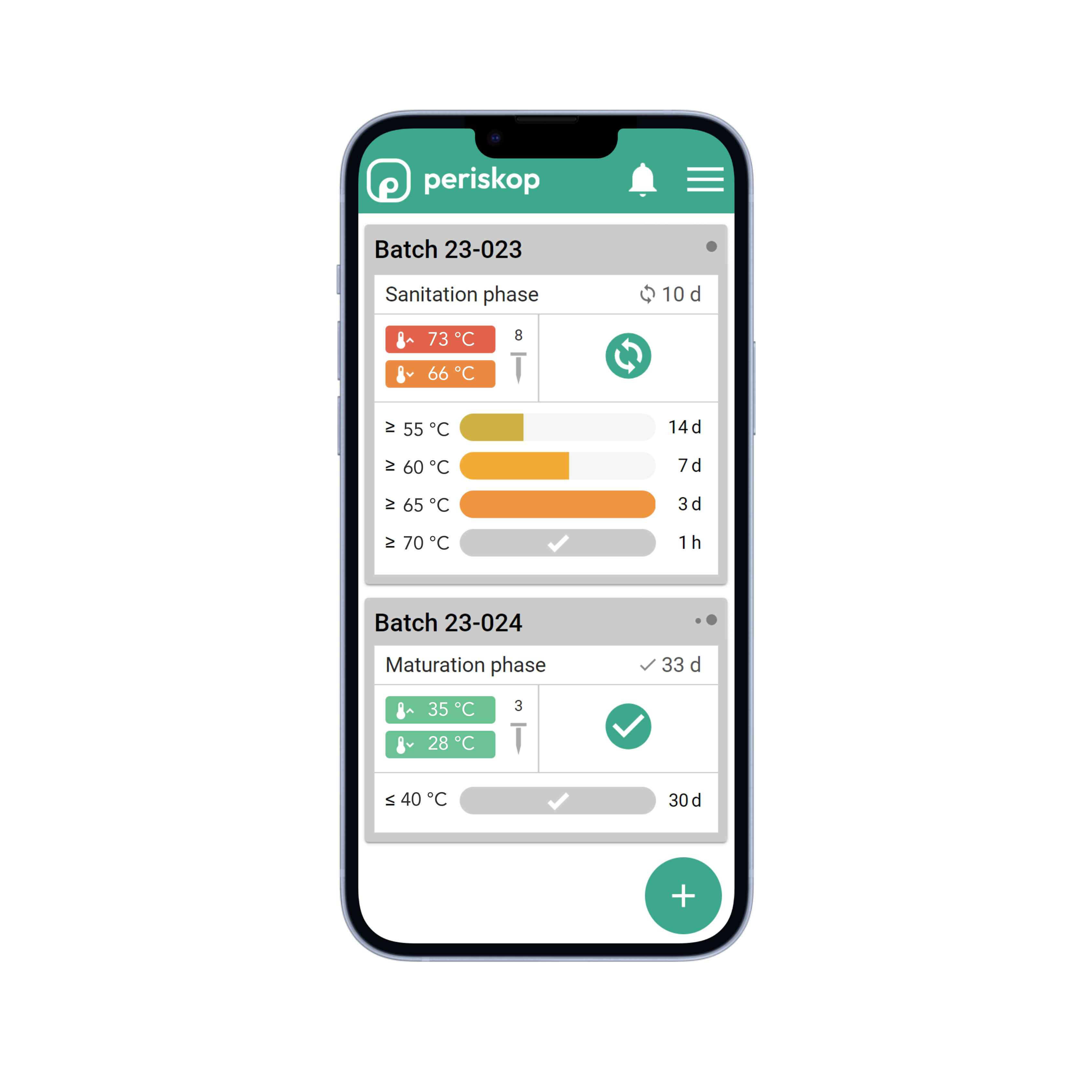

The Relay Controller regulates compost ventilation by adjusting airflow according to the batch temperature. For instance, during the sanitation phase, ventilation helps heat the compost, while in the maturation phase, it aids in cooling. This process continues until the temperature-time targets for each phase (e.g., ≥ 60°C for 24 hours) are achieved.

Ventilation cycles

In RC12 ventilation runs in cycles with a set duration to address specific heating or cooling requirements by adjusting the cycle parameters. Each cycle includes a total duration and a designated active ventilation time within that period. Cycle lengths can range from 10 to 60 minutes, with the ventilation time adjustable from 0 (no ventilation) to the full cycle length (continuous ventilation).

Optimal ventilation cycles are determined by the process phase (heating or cooling) and the current batch temperature. For example, during the sanitation phase, when ventilation is used to heat the batch, less ventilation is required as the batch temperature rises.

How does the RC12 compost ventilation system help lower energy costs?

The RC12 compost ventilation system helps reduce energy costs by optimizing airflow based on the specific heating or cooling needs of the compost batch. Operating ventilation fans consumes electricity, and the associated costs can vary greatly depending on the season and time of day. With the help of RC12 compost ventilation controller, ventilation cycles can be set in three different modes.

- Normal ventilation for regular hours

- Light ventilation for expensive hours

- No ventilation for the most expensive peak hours

The Periskop RC12 allows automation of the ventilation through monthly and hourly scheduling program.

Ready to try Periskop ventilation control?